Hybrid Power for the Electric Carriage

At first, I thought I might take a weed-whacker motor and chain

drive a 500W DC motor/generator similar to my main drive motors but that idea

just kept getting more and more complicated. Speed reduction, complicated mounting

brackets, voltage and current control, and so on....

So I started looking for a 4-stroke motor since I really didn't

want all the hassle of mixing gas and oil. Besides, 4-strokes are quieter and

don't smoke. I found this great little Honda 25cc motor that looked perfect.

I wasn't expecting it to come with a centrifugal clutch though.

Well it was that clutch that gave me the idea of mounting a

regular car alternator directly onto the motor. A 24 volt alternator would be

even better.

The only 24 volt alternators I could find were great big industrial

units. Way too heavy. The solution was to fit a 24 volt regulator to a standard

Toyota alternator. I'm not sure yet how well this will work. I may have to get

the rotor rewound to handle the higher voltage. I hope not though. The standard

alternators are built to supply power at fairly low idle rpm. (600 engine rpm

would be about 1200 alternator rpm on a car) The centrifugal clutch on the Honda

cuts in at 4000 rpm so the alternator would never spin slower than that.

Many thanks to Joe Falkner of Commercial Alternator and Starter

on Oshawa Ontario for all his help and advice with the alternator.

Had to do some minor machining to the alternator casting to

take the adapter plate. I used heli-coils in the aluminum for extra strength.

I also had to turn down the rotor shaft to take the clutch drum. When I tried

to thread the shaft, I got the die a little crooked and the drum wobbled like

crazy. So I cut off the crooked part, bored the shaft and ran a tap into it

using the lathe as a guide to keep it straight. I cut off the end of a 3/8"

grade 8 bolt and locktited it into the bore. That worked much better.

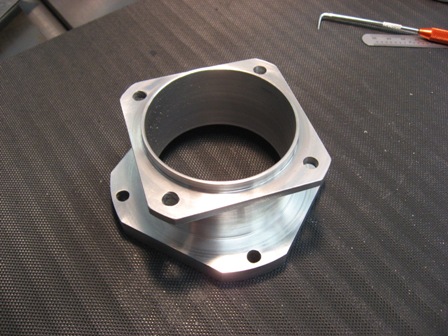

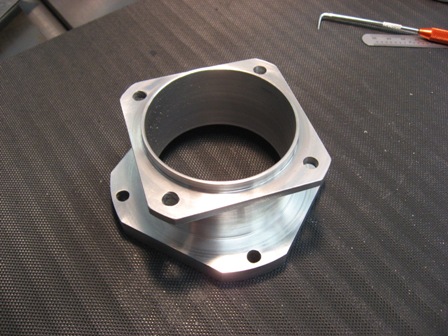

The adapter was machined from a 4-1/8"D x 2" bar

of aluminum.

The 45 deg offset in the flanges is for clearance to get a

wrench on the the bolts.

Since the alternator is mounted directly onto the motor, there

won't be any torque transferred to the mounting bracket. The bracket can be

fairly light.

Here are all the pieces ready to assemble.

Ready to mount. The centre of gravity ended up right at the

centre of the mounting bracket.

Now to start working on the electrics. I'm not sure how the

motor will react to the varying load of the alternator. It may slow the motor

down to the point that the clutch slips. I am going to try to fit a speed governor

to the motor. I think that will help.

It's now the first week of February and I AM SICK OF WINTER!